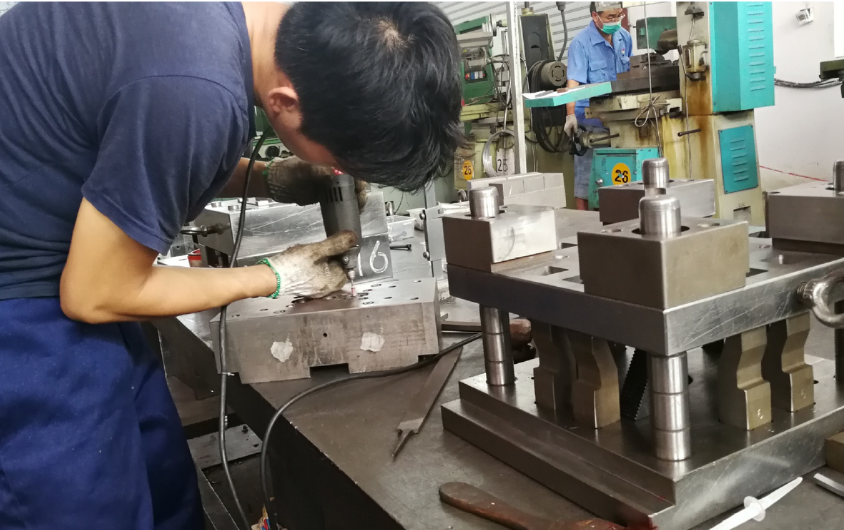

Jinen Plastic stands out as a premier professional plastic injection manufacturer, specializing in the design and production of high-quality plastic molds and molded products. Our extensive experience in the industry has equipped us with the expertise to handle a wide array of plastic components, particularly in sports equipment accessories and hardware plastic parts. We understand that the market demands precision and durability, which is why we utilize advanced injection molding techniques to ensure that every product meets the highest standards.

Our facility is strategically located in Xiamen, China, where we harness the power of modern technology to enhance production efficiency. With an output value reaching up to 20 million US dollars, we have the capacity to handle both small and large-scale orders without compromising quality. Our ISO9001-2015 certification reflects our commitment to maintaining rigorous quality management practices throughout the manufacturing process.

Furthermore, we recognize the importance of customization in today’s competitive landscape. Our team collaborates closely with clients to understand their unique needs and translate them into innovative solutions. Whether you require intricate designs or robust components, our professional plastic injection services are tailored to deliver products that not only meet but exceed your expectations.