Defining 'Perfect' Surface Finish for Custom Plastic Parts

Balancing Ra Values, Visual Appeal, and Functional Performance Requirements

The concept of a "perfect" surface finish for custom plastic parts isn't something that fits all applications. Instead, it's really about finding the right balance between measurable roughness (Ra values), how the part looks, and what it actually needs to do. Ra, measured in microns, basically tells us about those tiny peaks and valleys on a surface, which affects things like shine level, how light bounces off, friction when moving parts touch, and whether seals hold properly. What counts as good Ra changes quite a bit depending on the job at hand. For medical device seals, we need super smooth surfaces around 0.4 microns or less to stop bacteria from sticking, following ISO 13485 standards. But car interior parts care more about looking shiny (Class A gloss ratings above 90 GU) than being absolutely smooth. There's another twist too: textured surfaces with Ra between 3.2 and 6.3 microns help with grip but mess up optical clarity or cause problems with parts that need to slide smoothly against each other. And materials matter too. Crystalline plastics like PEEK naturally have smoother finishes compared to amorphous ones like ABS or PC, but they also tend to show more sink marks during molding because their crystals shrink differently when cooling down.

SPI A–D Standards: Matching Industry-Recognized Finishes to Your Custom Plastic Parts Application

The SPI classification system from the Society of the Plastics Industry gives manufacturers a common way to talk about mold finishes, which ultimately affects how parts look on the finished product. Let's break down the grades quickly. Grade A (or SPI-A) comes from diamond buffing and creates those super shiny surfaces we see in things like camera lenses and other optical equipment where reflection matters most. The Ra value here is under 0.012 micrometers, making it almost mirror-like. Moving on to Grade B (SPI-B), this one gets polished with fine stones and hits around 0.2 micrometers roughness. Great stuff for phones and gadgets where people want something glossy but not necessarily perfect. Grade C (SPI-C) uses grit abrasives to create those nice matte finishes at about 0.8 micrometers roughness. Appliances and medical gear really benefit from this because it hides scratches better and doesn't feel too slick to touch. Lastly there's Grade D (SPI-D), which involves bead blasting or shot blasting to get those textured surfaces above 1.6 micrometers roughness. These textures help with grip, hide manufacturing marks, and make weld lines less obvious. Picking the right grade saves money too. Nobody wants to spend extra bucks getting SPI-A finish on a simple bracket that doesn't need it. Mold shops charge upwards of fifteen grand per cavity sometimes when they go all out with premium finishes.

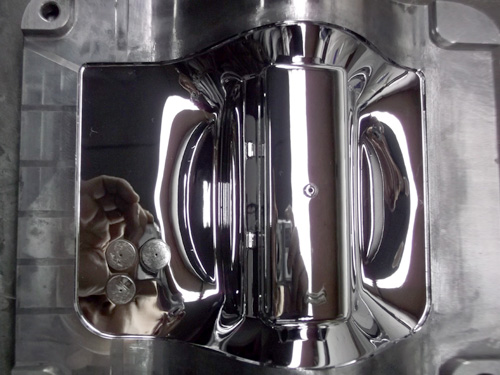

Mold Surface Engineering: The Critical First Step for Flawless Custom Plastic Parts

Achieving consistent surface quality in custom plastic parts begins—not with the part—but with the mold. Over 40% of injection molding rejections stem from surface finish defects, according to the Ponemon Institute‘s 2023 Manufacturing Quality Benchmark Report, underscoring that mold surface engineering is foundational to yield, aesthetics, and function.

Cavity Polishing, Laser Texturing, and PVD Coatings for Reproducible Surface Quality

- Cavity Polishing: Whether manual or CNC-assisted, high-precision polishing achieves Ra < 0.05 µm for optical-grade clarity and reduces ejection force by up to 60%, minimizing part distortion and mold wear.

- Laser Texturing: Digitally programmed lasers generate repeatable micro-patterns (0.5–100 µm depth) for anti-glare displays, ergonomic grips, or decorative motifs—with less than 5% variation across production batches.

- PVD Coatings: Titanium nitride (TiN) or diamond-like carbon (DLC) coatings extend mold service life 8–10× and suppress material buildup—especially critical when processing abrasive, glass-filled polymers. PVD-coated cavities maintain Ra stability within ±0.02 µm tolerance over 100,000+ cycles, eliminating the need for post-mold finishing in cosmetic applications.

Process & Material Optimization to Lock in Surface Consistency Across Production Runs

Surface consistency on custom plastic parts hinges on disciplined synchronization of process parameters and material selection. Even minor deviations—such as a 5°C melt temperature shift or 2% pack pressure fluctuation—can amplify flow marks, haze, or texture loss across large production runs.

Injection Molding Parameters That Directly Impact Gloss, Flow Marks, and Replication Fidelity

Getting the right balance between melt temperature, injection speed, and pack pressure is absolutely critical when working with different resins. If the melt gets too hot, it starts breaking down those stabilizers and pigments in the material, which leads to problems like inconsistent gloss or hazy spots on finished parts. On the flip side, when fill speeds are too slow, the plastic cools down too quickly against the mold walls, creating visible flow marks and making it hard to get good texture reproduction. Maintaining steady pack pressure throughout the cycle helps prevent those annoying sink marks that tend to show up especially around structural features like ribs and bosses. This matters a lot because proper pack pressure ensures parts maintain their intended dimensions and flat surfaces, something manufacturers need for components that have to fit together with very tight tolerances.

Material Selection Guide: ABS, PC, PP, and PEEK – Surface Finish Capabilities and Limitations for Custom Plastic Parts

Each thermoplastic brings distinct surface implications:

- ABS: Delivers high-gloss, easy-polish finishes but suffers UV-induced yellowing without stabilizers.

- Polycarbonate (PC): Offers exceptional clarity and scratch resistance, yet develops stress whitening around sharp corners or under high clamp pressure.

- Polypropylene (PP): Provides excellent chemical resistance and reliable texture transfer, though its low surface energy impedes bonding or painting without plasma or flame treatment.

- PEEK: Maintains dimensional and surface stability under extreme heat and load, but its high melt viscosity demands optimized gate design and tool steel hardness to prevent jetting and poor cavity fill.

Low-viscosity resins—like unfilled PP—replicate fine textures more reliably than filled grades. Anticipating these behaviors during material selection prevents downstream corrections for matte streaks, weld line visibility, or inconsistent grain definition.

Design for Manufacturability (DFM): Preventing Surface Defects Before Tooling Begins

Design for Manufacturability or DFM moves surface quality checks much earlier in the process, catching problems before any molds are actually made. Instead of dealing with issues like sink marks or flow lines after parts come off the production line, DFM brings together physics simulations and real manufacturing knowledge to look at things like draft angles, how even the wall thickness is, where gates should go, and proper radii during initial design stages. When engineers run digital flow analysis, they can see exactly where problems might happen with the resin as it fills the mold. This shows spots likely to cause cosmetic issues such as areas where the material hesitates and creates blush or jetting effects, or structural weak points like thin sections that tend to warp when cooling down. Good design practices include making sure walls are consistent in thickness, avoiding sudden changes in shape, and adding enough draft angle typically around 1 degree or more especially important for textured surfaces. These design choices help ensure the mold fills properly and parts eject without damage, cutting back on the need for expensive hand finishing work later on. The collaboration between product designers and manufacturing teams upfront saves money on tooling revisions, speeds up getting products to market, and makes sure the final parts meet both looks standards and function requirements no matter what volume level the production runs at.

Targeted Post-Processing Techniques for Final Surface Refinement of Custom Plastic Parts

When to Choose Flame Polishing, Vapor Smoothing, or Precision Bead Blasting

Post-processing serves as the final calibration—not a workaround—for achieving exact surface specifications. The optimal method depends on geometry, material, volume, and functional intent:

- Flame Polishing: Best for thick-sectioned, thermally stable parts (e.g., acrylic or polycarbonate automotive trim), where a brief, controlled flame melts surface peaks to boost gloss rapidly (<5 minutes/part). Thin-walled or heat-sensitive parts risk distortion and are excluded.

- Vapor Smoothing: Ideal for complex, enclosed geometries—such as medical device housings with internal channels—where mechanical methods cannot reach. Chemical vapors (e.g., acetone for ABS, THF for PC) dissolve microscopic irregularities, yielding biocompatible, pore-free finishes with no dimensional change. Reaction stabilization adds 15–30 minutes per batch.

- Precision Bead Blasting: Delivers highly repeatable matte or satin textures (Ra 0.8–3.2 µm) with <5% variance across batches—critical for mating surfaces, industrial enclosures, or safety-critical components requiring consistent friction. Unlike sandblasting, precision bead blasting uses calibrated media and pressure control to avoid undercutting or edge rounding.

Choose vapor smoothing for intricate, functional assemblies; flame polishing for high-volume, thick optical elements; and precision bead blasting when texture uniformity, grip control, or defect masking is paramount.

Frequently Asked Questions

-

What does Ra value mean in surface finishing?

Ra value represents the average roughness of a surface, measured in microns. It indicates the height of peaks and depths of valleys on the surface, affecting shine, friction, and seal retention.

-

How does SPI grading affect surface finishes?

SPI grades classify mold finishes from ultra-smooth (SPI-A) to textured (SPI-D), affecting gloss and roughness suited for various applications like optical clarity or grip.

-

What are common post-processing techniques for plastic parts?

Common techniques include flame polishing for high-gloss surfaces, vapor smoothing for intricate geometries, and precision bead blasting for uniform textures.

-

Why is Design for Manufacturability (DFM) important?

DFM integrates early-stage checks to prevent defects, optimize drafts, gate placements, and wall consistency, reducing post-production corrections and speeding up market readiness.

Table of Contents

- Defining 'Perfect' Surface Finish for Custom Plastic Parts

- Mold Surface Engineering: The Critical First Step for Flawless Custom Plastic Parts

- Process & Material Optimization to Lock in Surface Consistency Across Production Runs

- Design for Manufacturability (DFM): Preventing Surface Defects Before Tooling Begins

- Targeted Post-Processing Techniques for Final Surface Refinement of Custom Plastic Parts