Micro Injection Molding: Enabling Precision in Medical and Electronics Applications

Breakthroughs in precision and miniaturization driving advancements in medical devices and consumer electronics

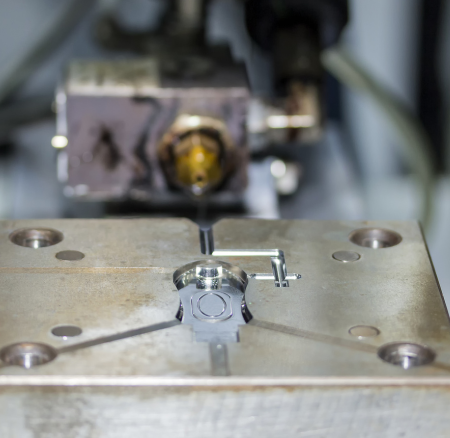

The micro injection molding process can achieve tolerances below 50 microns, which makes it indispensable for making those really tiny medical devices we see these days, including things like neural implants and sensors that break down inside the body. At this level of precision, the parts work reliably when they need to interface with living tissue, and they also meet those strict ISO 13485 requirements that medical manufacturers have to follow. Looking at consumer gadgets, this same technology lets companies build intricate parts inside wearable tech, from microscopic gears to super slim connectors that fit in tight spaces. The market for all this stuff is expanding fast because people want smaller and smaller devices everywhere. Industry forecasts suggest the global medical injection molding sector will hit around $10.8 billion by 2031, growing steadily at about 5.3 percent each year. What's exciting is how these improvements are opening up entirely new possibilities too. Take endoscopic cameras for instance, many models now feature specially molded micro lenses that provide crystal clear images even though the whole camera has to fit through tubes less than a millimeter wide.

Material and thermal control challenges in high-speed micro molding processes

Getting nanoscale precision right means dealing with some serious thermal and material control issues. When working at micro volumes, the way materials behave changes dramatically. Viscosity fluctuations happen around three times faster compared to regular injection molding processes, which makes real-time adjustments absolutely necessary. The cooling process is another challenge altogether. Different parts of the mold need varying cooling rates to stop premature crystallization from happening. Some systems now have built-in thermal sensors that can keep temperature variations down to just plus or minus 0.2 degrees Celsius during those intense injection cycles. And let's not forget about the pressure aspect either. High-speed processing really ramps things up. Pressures often go beyond 2,500 bar, so the tooling needs to be extremely precise with tolerances below 5 microns. Manufacturers rely heavily on advanced mold flow simulations these days to predict how nanofillers will distribute throughout polymers. This helps reduce those annoying inconsistencies that might otherwise wreck the structural integrity of delicate microfluidic channels.

Case study: Nanocomposite-based micro molding in insulin delivery systems

The tiny world of micro molding has become essential for managing diabetes thanks to its ability to create incredibly precise parts for insulin delivery systems. Special nano-reinforced plastics are making these pumps much more reliable because they stay stable even after being sterilized repeatedly, plus they allow for super fine control over medication release. The materials can handle well over 100 thousand operation cycles, which is exactly what regulators require for medical devices. Some recent tests lasting about three months found that these new components cut down on tiny dosing mistakes by nearly 40% when compared to older manufacturing methods. Manufacturers have also managed to produce complex shapes like those tapered micro nozzles with tolerances below 10 microns, something that solved annoying wear problems from previous versions and ultimately leads to better results for people living with diabetes.

Multi-Material and Overmolding Innovations for Functional Part Integration

Overmolding and insert molding techniques enhancing design flexibility and component durability

Overmolding and insert molding bring together different materials during one manufacturing run, cutting down on extra assembly work while making products stronger overall. Engineers can actually mix hard base materials with softer outer layers. Think about attaching heat-resistant plastics to rubber-like materials that absorb shocks and vibrations. This creates solid parts where stress points are built right in. Parts made this way last roughly three times longer before breaking down compared to those put together piece by piece. Plus, these joined surfaces don't let water get inside or come apart easily, so they hold up much better when exposed to harsh conditions over time.

Applications in automotive and consumer goods: Combining aesthetics with performance

Dashboard controls in cars now often have these overmolded surfaces that feel nice to touch and light up at night, which helps drivers avoid getting distracted when it's dark out. The material also stands up pretty well against sun damage over time. Take toothbrush handles as another example. Manufacturers mold them with an outer layer that fights germs while keeping a tough inner core so they don't break easily even if dropped from quite high, maybe around two meters or so. These advances in plastic molding let companies create better grip sensations and comfortable shapes for products without making them weaker. For designers working on everything from car parts to everyday items, this means they can finally get what they want in terms of look and feel without compromising how well something actually works.

Addressing material compatibility and interfacial adhesion challenges

Successful multi-material molding depends on careful selection and processing of compatible materials. Key factors affecting bond strength include melt temperature differences, polymer chemistry, and shrinkage mismatch:

| Factor | Impact on Adhesion | Mitigation Strategy |

|---|---|---|

| Melt temperature gap | >20°C differences cause weak bonds | Thermal buffer layers (2024 polymers study) |

| Polymer chemistry | Non-polar/polar combinations fail | Compatibilizer additives |

| Shrinkage mismatch | Internal stresses cause delamination | Glass-reinforced substrates for dimensional stability |

Plasma surface treatment improves adhesion by 60% between traditionally incompatible materials. ASTM-certified simulation protocols now predict interfacial failures before tooling fabrication, reducing development costs by 35%. By optimizing cooling temperature profiles, manufacturers achieve 97% adhesion reliability in medical device validation trials (DIN ISO 10993:2023).

Advanced Materials Revolutionizing Plastic Molding Performance

Nanocomposites and High-Performance Polymers (e.g., PAEK) for Strength and Thermal Stability

Materials made with graphene, carbon nanotubes, or special minerals can achieve tensile strengths over 150 MPa, which is around 40% stronger than regular plastics. That kind of strength makes these nanocomposites perfect for tough industrial applications where failure isn't an option. Take PAEK polymers for example they stay dimensionally stable even when exposed to continuous heat of about 250 degrees Celsius, something that matters a lot in airplane parts and car engine compartments. Another big plus? These new materials cut down production cycle times by approximately 30% because they cool much quicker during manufacturing. Industry tests from recent thermal molding studies back this up, showing real world benefits for manufacturers looking to improve efficiency without sacrificing quality.

Sustainable Bio-Based Resins Reducing Environmental Impact Without Compromising Quality

Resins made from agricultural leftovers and algae are finally catching up to traditional ABS plastic when it comes to strength and durability, all while cutting down on carbon emissions by almost half, per recent market reports from 2024. Recent breakthroughs in enzyme-based manufacturing processes have led to new versions of PLA that can handle temperatures around 120 degrees Celsius, making them good candidates for things like lunchboxes and other food storage items that need to withstand hot water. Around three out of four manufacturers are already using these eco-friendly materials for medical devices that meet FDA standards, showing that green alternatives don't have to sacrifice quality. The plastics industry is slowly but surely shifting toward sustainable options without compromising what works best for production needs.

Smart Manufacturing and Industry 4.0 Integration in Molding Workflows

Industry 4.0 technologies are transforming plastic molding through interconnected systems that enhance visibility, control, and efficiency.

IoT and AI-driven real-time monitoring for improved process control and quality assurance

Sensors built into the system keep track of temperature changes, pressure levels, and how long each molding cycle takes. All this information gets sent straight to cloud-based AI platforms as it happens. The smart algorithms then tweak settings on their own to keep everything within really tight margins, around plus or minus 0.01 millimeters. When it comes to quality checks, these advanced systems can spot problems with material thickness or cooling speed almost instantly. Factories report that this has cut down waste materials by roughly 20% give or take depending on conditions. Such precise control makes all the difference when manufacturing parts that need to meet strict dimensional requirements.

Predictive maintenance and automation reducing downtime in high-volume production

Modern machine learning tools look at how machines vibrate and perform hydraulically to spot potential breakdowns somewhere between two days and three days ahead of time. In many factories these days, robots actually swap out parts that have seen better days, such as those little metal sticks called ejector pins, while the main production line takes its regular breaks. This approach has slashed unexpected stoppages by roughly 35 to 45 percent in car manufacturing facilities. Meanwhile, automated systems for drying and moving resins keep things just right when it comes to moisture content. Getting this balance right matters because too much or too little moisture can ruin entire batches. These systems help maintain consistent quality through thousands upon thousands of production runs without anyone having to constantly check on them manually.

Balancing innovation with data security in connected molding environments

When production networks expand, encrypted communication becomes essential for keeping mold design information secure as it moves between factory equipment and central business systems. Companies are implementing role-based access controls these days to keep sensitive manufacturing data out of unauthorized hands. Some manufacturers also set up separate backup systems that aren't connected to main networks just in case something goes wrong with cybersecurity. Most forward-thinking plants run regular security checks on their connected devices too. These tests help find holes in the system before hackers do. The whole point is to maintain good security standards while still allowing engineers to innovate and improve processes without constant roadblocks from over-cautious IT policies.

Hybrid Approaches: Integrating 3D Printing with Traditional Plastic Molding

Additive manufacturing accelerating mold prototyping and enabling rapid tooling

When it comes to mold development, additive manufacturing has really changed the game, cutting down what used to take weeks into just a few days. The whole process works differently now because we can print those tooling inserts straight from CAD files instead of waiting around for CNC machining. This means companies get their designs validated much quicker, somewhere between 50 and 70 percent faster than before. Looking at industry numbers, most manufacturers report that their prototyping cycles shrink by about 40 to 60 percent when they switch to materials like temperature-resistant photopolymers or even hybrid metal prints. What's particularly interesting is how this technology handles complex shapes that traditional methods simply couldn't manage, all while saving around 35% on pre-production expenses according to recent studies. Parts are ready for functional testing within three days after the first design sketch, which speeds things up significantly for products like electronic housings and medical devices where timing matters a lot. Plus, these integrated approaches keep measurements accurate within plus or minus 0.1 millimeters, something that was always problematic with older rapid tooling techniques.

Case study: Low-volume production using 3D-printed molds in hybrid workflows

One medical device company recently switched to carbon fiber reinforced polymer molds when they needed to produce around 300 biocompatible polycarbonate housing units for a new product line. Production time per part dropped below 90 seconds, and these printed molds lasted through about 400 injection cycles without losing their shape or accuracy (staying within 0.2mm tolerance). The conformal cooling channels inside these molds were specially designed using additive manufacturing techniques, which cut down on cooling time enough to reduce overall cycle times by roughly 40%. From getting the CAD designs approved all the way to producing the first working samples, everything went much faster too – just 11 days instead of the usual 32 days required with traditional metal tools. Switching to this mixed method saved them nearly $46k compared to what aluminum molds would have cost. Plus, if there's ever a need to tweak the design later on, they can simply reprint the mold rather than waiting weeks for new tooling. This makes it an excellent option for smaller production batches where flexibility matters as much as cost savings.

FAQ

What is micro injection molding?

Micro injection molding is a precision manufacturing process used to create very small components with tight tolerances, often used in medical devices and electronics.

Why is thermal and material control important in micro molding?

Thermal and material control is crucial because at micro volumes, materials behave differently, requiring precise management to prevent issues like premature crystallization and to ensure consistent quality.

How does Industry 4.0 improve injection molding processes?

Industry 4.0 technologies enhance injection molding by enabling real-time monitoring and control, predictive maintenance, and improved quality assurance through interconnected smart systems.

What are the benefits of using bio-based resins in molding?

Bio-based resins offer environmental benefits by reducing carbon emissions and using sustainable materials without compromising on the strength and durability required for various applications.

How does 3D printing integrate with traditional molding?

3D printing accelerates the mold prototyping process, allowing for rapid tooling development and flexibility in design modifications, thereby reducing time and costs in production.

Table of Contents

- Micro Injection Molding: Enabling Precision in Medical and Electronics Applications

- Multi-Material and Overmolding Innovations for Functional Part Integration

- Advanced Materials Revolutionizing Plastic Molding Performance

- Smart Manufacturing and Industry 4.0 Integration in Molding Workflows

- Hybrid Approaches: Integrating 3D Printing with Traditional Plastic Molding

- FAQ