China Jinen Plastic Co., Ltd. – Custom plastic parts manufacturer with end-to-end solutions. 20+ years of R&D expertise, advanced tech, and quality-driven production.

We provide detailed prototype design of molds to help you optimize the manufacturing cost of mass production. Our prototype design team is efficient and fast, and can produce drawings within 24 hours at the fastest. Ensure that all design adjustments are completed as early as possible to reduce costs and time to market for you.

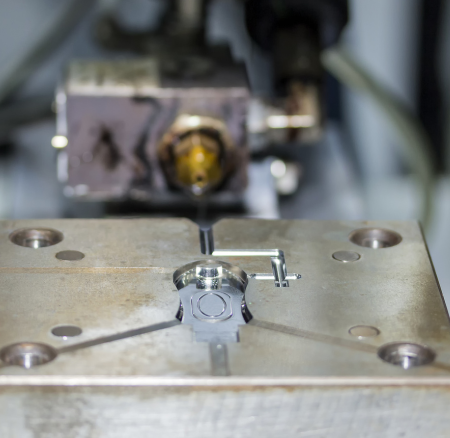

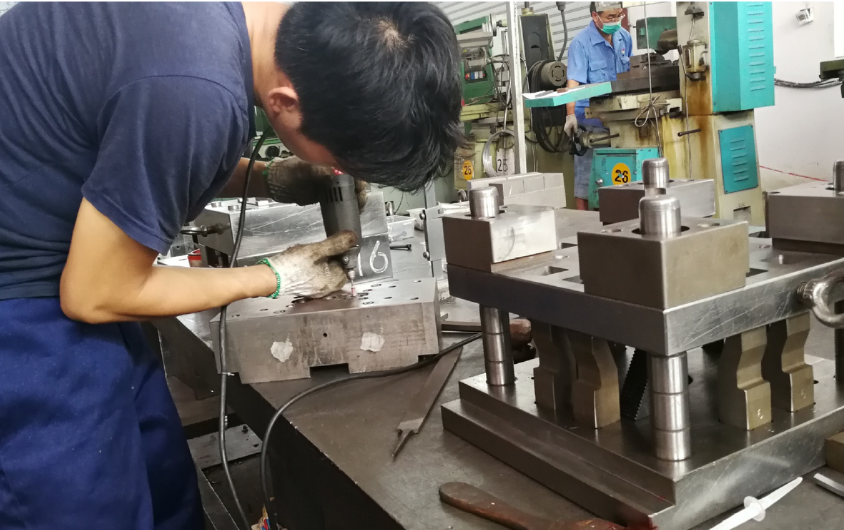

We have an engineering team that develops injection molds independently. The team members include 5 engineers with more than 10 years of experience and 10 advanced mechanical equipment to meet your precise requirements for mold making.

We have 40 80-1300t injection molding machines, with 24-hour efficient production, to help you solve urgent orders. We use high-strength plastic raw materials and a variety of colors for you to choose from, ensuring that your products are both functional and beautiful.

In the field of rubber and silicone molding, we have deeply cultivated precision manufacturing processes and material innovation, and have accumulated rich industry practical experience. In view of the differences in the characteristics of rubber and silicone, we have customized the development of molding technologies such as molding, injection molding, and extrusion, covering multiple fields such as automotive seals, medical devices, electronic insulation components, and consumer products.

Through customized molds, multi-axis manipulator precise positioning and Moldflow simulation optimization, the yield rate can reach over 98%. It is compatible with a variety of metal substrates such as copper, aluminum, and stainless steel, and supports the mass production of complex and special-shaped inserts, helping customers shorten the assembly chain and improve product reliability.

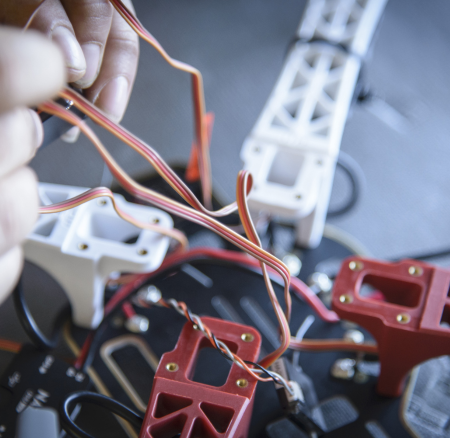

We focus on the optimization of the post-process of precision parts, and are good at multi-material composite assembly (plastic/metal/silicone), CNC precision finishing and surface treatment (polishing, anodizing). Through the design of automated assembly lines, logo silk screen printing and surface painting, and strict implementation of the ISO 9001 system, we achieve a full-process technical closed loop from single-piece processing to modular delivery.

The plastic products we make are widely used in various fields. We have rich experience in related industry cases and can provide you with high-quality products.

Watch via the following platforms :

We have been a professional plastic manufacturer in China since 2008.Passed ISO9001-2015 and 40 design patents.We have a full set of equipment for producing molds and plastic products, a total of 40 sets,with a daily production of 50,000 pieces.24-hour online customer service to provide you with good solutions.The company's main business is customized plastic products, customized plastic silicons products, plastic mold production, hardware products and electronic products.

Company Years

Product Qualification Rate

Partner

Project

We show our customers' project cases, which implement our consistent high quality requirements. From small parts production to complex finished product assembly, we will implement unified high standards to meet your needs and ensure that you receive the best quality products.

Please Keep An Eye On The Developments Of Our Company